The tool change does not work, the PLC report number 1000 is displayed on the screen (the report address A0000.0 indicates that the tool change time is too long), and the report number is 100. The report address A0000.3 indicates that the lock signal is not received. ).

Therefore, the inspection and maintenance process: first shut down and restart the machine, and observe whether there is a prompt to check whether the machine cannot be used normally due to a software problem or improper operation. The alarm is still displayed after the machine is turned on. The CNC lathe still cannot Use it normally, and at the same time eliminate the lathe failure caused by software or improper operation.

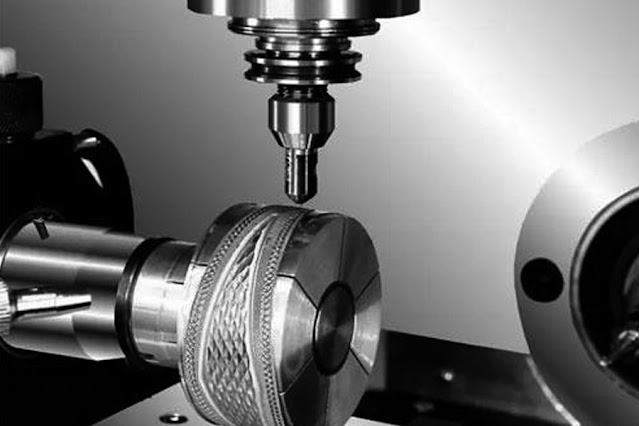

Because the tool change process of the tool is that the tool post first performs forward rotation for the tool change action. After the tool post reaches the specified position, the reverse meshing is necessary, so first check the electrical circuit related to the tool post conversion process. For the device, check whether the electrical circuit is damaged, burned, or loose, and whether the related relays and contactors are damaged.

After inspection, everything is normal. Then check the electrical circuit components related to the tool holder's tool change reversal engagement and locking process. It is found that the contact of the contactor that controls the tool holder reversal is broken. The multimeter test basin found that the contactor is often The closed contact has a slight resistance value, and the measured position is I, which is equivalent to an open circuit). Solution: After replacing the contacts of the contactor, the CNC lathe resumes normal operation.